In the world of construction, building materials and techniques are constantly evolving to meet the demands of modern architecture, sustainability, and environmental concerns. One such material that has undergone significant transformation over the years is Reinforced EPS (Expanded Polystyrene) structural panels. From their humble beginnings as a lightweight, insulating material to their current status as a versatile and durable building component, Reinforced EPS panels have come a long way.

Table of Contents

ToggleEPS In Early Days:

The story of EPS begins in the 1940s when scientists first discovered the process of expanding polystyrene beads into a lightweight, porous material. Initially used as a packaging material, EPS was later adopted by the construction industry due to its exceptional insulation properties and low cost. In the 1950s and 1960s, EPS began to be used in building applications, primarily as a filling material for walls and roofs.

The Advent of Reinforced EPS

The game-changer came in the 1970s with the development of Reinforced EPS (EPS-RC) panels. By incorporating reinforcing materials like fiberglass or polyester mesh into the EPS core, manufacturers were able to create a stronger, more durable product that could withstand various environmental conditions. These panels quickly gained popularity in the construction industry, particularly in the production of pre-fabricated building components like wall panels and roof tiles.

Advancements in Technology and Materials

The 1980s and 1990s saw significant advancements in EPS technology and materials. Manufacturers began to develop new types of EPS, such as high-density EPS (HDEPS) and high-strength EPS (HSEPS), which offered improved compressive strength and resistance to impact. The introduction of specialized adhesives and bonding agents also enabled the creation of more complex panel designs and larger panel sizes.

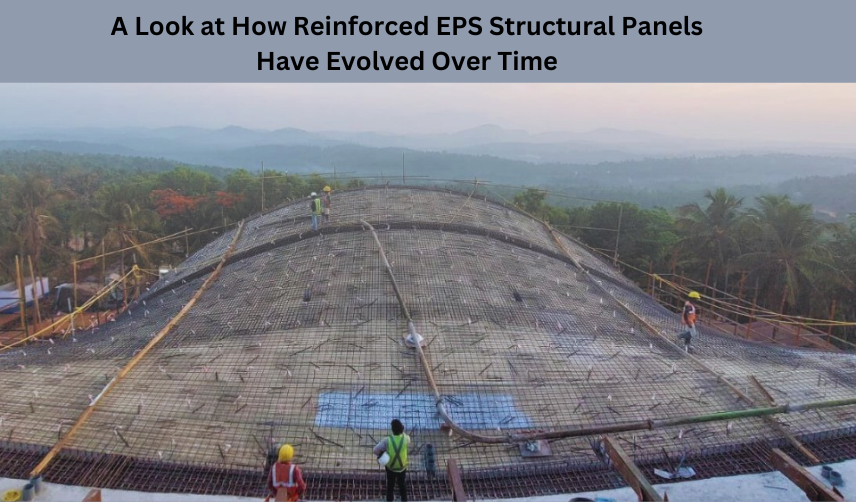

Modern Era: The Rise of Reinforced EPS Panels

The 21st century has witnessed a remarkable growth in the use of Reinforced EPS panels in various construction applications. Today, these panels are widely used in:

Pre-fabricated building components: Wall panels, roof tiles, and floor panels are just a few examples of the many pre-fabricated building components that can be made using Reinforced EPS.

Structural elements: Reinforced EPS panels are used as structural elements in building design, such as load-bearing walls, partitions, and even entire buildings.

Insulation and energy efficiency: The high thermal insulation properties of EPS make it an ideal material for energy-efficient buildings, reducing energy consumption and carbon emissions.

Acoustic insulation: The sound-absorbing properties of EPS make it an effective material for reducing noise pollution in buildings.

Benefits of Reinforced EPS Panels

So, what makes Reinforced EPS panels so popular in modern construction? Here are some key benefits:

Lightweight:

Reinforced EPS panels offer a notable advantage in weight compared to conventional building materials, facilitating simpler transportation and installation processes.

High insulation values:

The high thermal insulation properties of EPS reduce energy consumption and minimize environmental impact.

Durable:

With proper installation and maintenance, Reinforced EPS panels can last for decades without significant degradation.

Cost-effective:

Compared to traditional building materials, Reinforced EPS panels are often more cost-effective, making them an attractive option for budget-conscious builders.

Versatility:

Available in various shapes, sizes, and configurations, Reinforced EPS panels can be adapted to meet specific design requirements. As we look to the future of construction, it’s clear that Reinforced EPS panels will continue to play a vital role in building design and innovation. Advances in technology will likely lead to:

Improved performance:

Research will focus on enhancing the thermal insulation properties, durability, and acoustic performance of Reinforced EPS panels.

New applications:

As construction techniques evolve, we’ll see Reinforced EPS panels being used in new applications, such as advanced infrastructure projects or even off-site manufactured housing.

Sustainability and Environmental Considerations

In recent years, sustainability has become a paramount concern in the construction industry. Reinforced EPS Structural Panels have emerged as a sustainable alternative to traditional building materials due to several factors:

Energy Efficiency:

The exceptional thermal insulation properties of EPS reduce heating and cooling costs, contributing to energy conservation.

Recyclability:

EPS is fully recyclable, minimizing waste and reducing the environmental impact of construction projects.

Reduced Carbon Footprint:

The lightweight nature of EPS panels translates to lower transportation emissions and overall carbon footprint compared to heavier building materials.

Conclusion

In conclusion, the evolution of Reinforced EPS structural panels has been marked by significant advancements in technology, materials science, and manufacturing processes. As we look back on this journey, it’s clear that these versatile panels have become an essential component of modern construction practices. With their impressive range of benefits, including energy efficiency, durability, and cost-effectiveness, it’s no wonder that Reinforced EPS panels are set to continue playing a vital role in shaping the future of building design and innovation.

Watch Video

FAQs About Reinforced EPS Structural Panels

1. What are Reinforced EPS Structural Panels, and how do they differ from traditional building materials?

Reinforced EPS Structural Panels are innovative construction elements that combine expanded polystyrene (EPS) with reinforcement materials like steel or fiberglass mesh. Unlike traditional building materials such as concrete or wood, EPS panels offer exceptional lightweight properties, excellent thermal insulation, and versatility in design. They can serve as both insulation and structural components, providing an efficient solution for modern construction projects.

2. Are Reinforced EPS Structural Panels durable enough to be used as structural elements in buildings?

Yes, advancements in reinforcement techniques have significantly enhanced the structural integrity of EPS panels. By integrating steel or fiberglass mesh into the EPS matrix, these panels can withstand considerable loads, making them suitable for use in walls, floors, and roofs. Additionally, modern composite materials further improve strength-to-weight ratios, ensuring durability without sacrificing performance.

3. What are the environmental benefits of using Reinforced EPS Structural Panels?

Reinforced EPS Structural Panels offer several environmental advantages over traditional building materials. Firstly, their lightweight nature reduces transportation emissions and overall carbon footprint. Secondly, EPS is fully recyclable, minimizing waste and promoting circular economy principles. Moreover, the panels’ exceptional thermal insulation properties contribute to energy efficiency, reducing heating and cooling costs and lowering greenhouse gas emissions.

4. How do Reinforced EPS Structural Panels contribute to sustainable construction practices?

Reinforced EPS Structural Panels play a vital role in promoting sustainable construction practices through various means. They offer energy-efficient solutions for building envelopes, reducing the overall energy consumption of structures. Additionally, their recyclability and low environmental impact make them an eco-friendly choice for construction projects. By integrating these panels into building designs, architects and builders can contribute to the reduction of carbon emissions and promote sustainable development.

Also, Read

Enhancing Construction And Renovation With Reinforced EPS Structural Panels