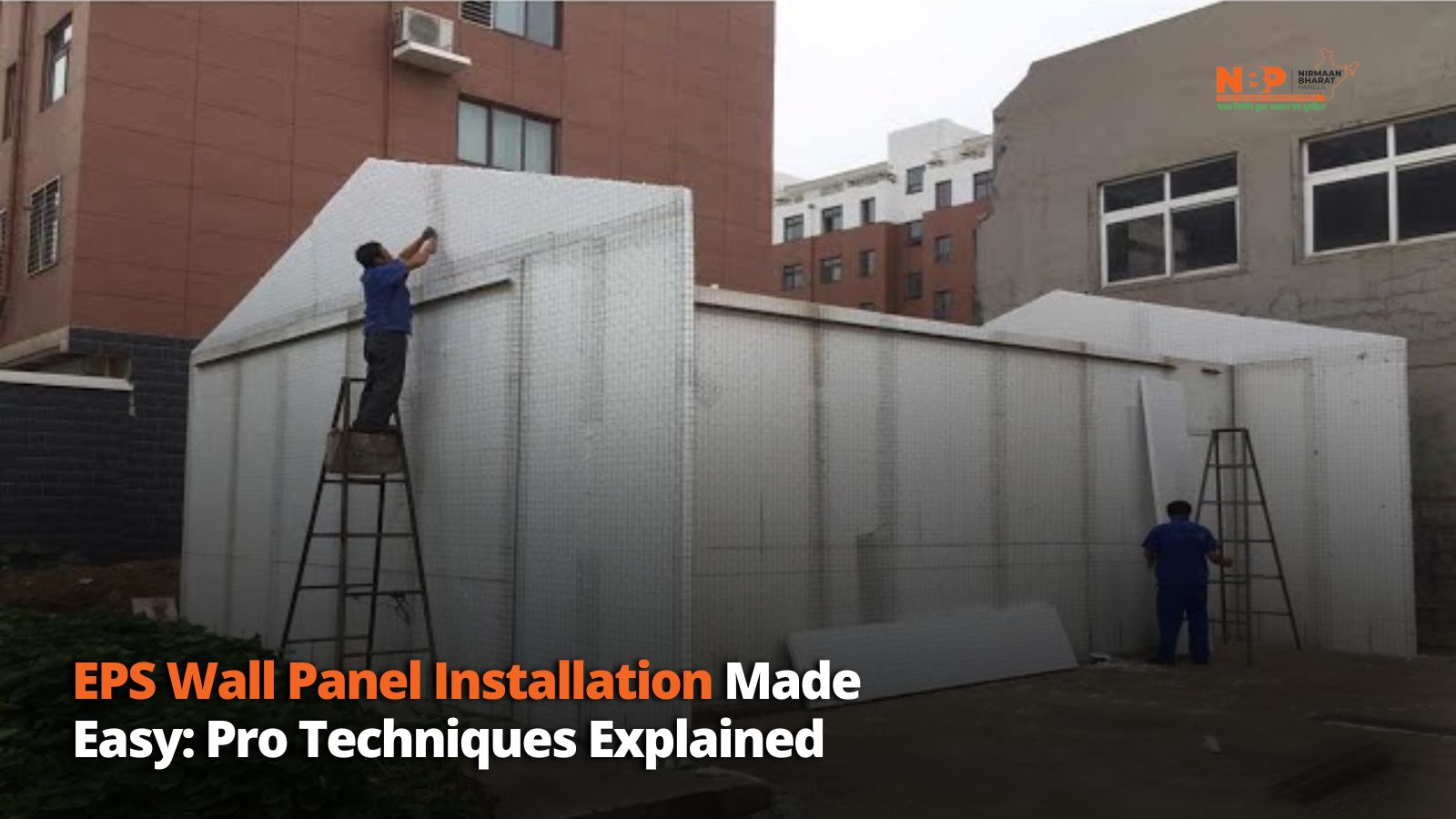

Expanded Polystyrene (EPS) wall panels have become a popular choice in construction due to their lightweight, energy efficiency, and ease of installation. These versatile panels are widely used for residential, commercial, and industrial buildings. Suppose you’re planning to install EPS wall panels. In that case, this guide, EPS Wall Panel Installation Made Easy: Pro Techniques Explained, covers everything you need to know, including the materials required, the step-by-step installation process, and the proper techniques to achieve flawless results.

Table of Contents

ToggleWhat Are EPS Wall Panels?

EPS wall panels are advanced prefabricated construction materials crafted using expanded polystyrene, a versatile and lightweight foam. These panels are typically encased between layers of steel or cement boards, combining strength with a lightweight structure. Known for their exceptional thermal insulation, they help maintain energy efficiency by regulating indoor temperatures. Additionally, their soundproofing capabilities make them ideal for creating quiet and comfortable spaces. Durable and easy to install, EPS wall panels are a sustainable choice for modern construction projects.

Benefits of EPS Wall Panels

1. Energy Efficiency: EPS wall panels provide excellent thermal insulation, minimizing heat transfer. This reduces dependency on heating and cooling systems, significantly lowering energy costs.

2. Lightweight: These panels are incredibly lightweight, making them easy to transport and handle. This reduces labour effort and transportation expenses, enhancing overall project efficiency.

3. Durability: Designed to withstand harsh conditions, EPS panels are resistant to moisture, pests, and wear. They ensure long-term performance and minimal maintenance.

4. Eco-Friendly: Made from recyclable materials, EPS panels contribute to sustainable construction practices. Their low environmental impact aligns with modern green building initiatives.

5. Quick Installation: The pre-fabricated design of EPS panels allows for seamless and swift installation. This accelerates project timelines and reduces construction delays.

Tools and Materials You’ll Need

Before commencing the installation, please assemble the following tools and materials:

- EPS wall panels

- Measuring tape

- Spirit level

- Utility knife or power saw

- Adhesive or bonding agent (polyurethane foam or construction glue)

- Anchors or screws

- Drill with appropriate bits

- Plastering tools (for finishing)

- Sealant (silicone or polyurethane-based)

Step-by-Step Guide to EPS Wall Panel Installation

Step 1: Prepare the Site

Clear the Area: Ensure the installation site is free of debris, dust, and obstacles. This will make the installation process smoother and prevent any damage or interruptions.

Check the Base: The surface should be level and smooth for optimal adhesion. If needed, use a spirit level to check for irregularities and make adjustments with a levelling compound.

Step 2: Measure and Plan

Take Accurate Measurements: Measure the dimensions of the wall carefully to determine the correct size and number of panels needed. This helps prevent mistakes and ensures a precise fit.

Mark Positions: Use a pencil or chalk to mark where the panels will be installed on the wall. This helps in aligning each panel accurately during installation.

Step 3: Cut Panels to Size

Trim Panels as Needed: Use a utility knife or a power saw to cut the panels to the desired dimensions, ensuring a precise fit for your space. Take your time for clean cuts that maintain the integrity of the panel.

Smooth Edges: Sand down any rough or sharp edges to create a seamless, professional finish. This step ensures safety and helps the panels blend perfectly with each other.

Step 4: Apply Adhesive

Select the Right Adhesive: Choose a construction-grade bonding agent specifically designed for EPS panels. This will ensure a strong and long-lasting bond.

Apply Adhesive Evenly: Spread the adhesive evenly on the back of the panel or directly on the wall surface. Use a trowel or a notched spreader to apply the adhesive uniformly for better adhesion.

Step 5: Position the Panels

Align Carefully: Place the first panel against the wall, ensuring it aligns precisely with the marked position. This sets the foundation for the rest of the installation.

Press Firmly: Apply firm pressure to secure the panel in place, allowing the adhesive to bond effectively. This step is essential for stability.

Check Alignment: Use a spirit level to ensure the panel is straight and aligned. Adjust as needed before moving on to the next panel.

Step 6: Secure the Panels

Drill and Anchor: Drill holes through the panels and insert anchors or screws to secure them. This provides added stability, especially in high-traffic or load-bearing areas.

Reinforce Edges: Add extra screws or fasteners along the edges of the panels to ensure they are firmly held in place and won’t shift over time.

Step 7: Fill Gaps and Seams

Seal Gaps: Use a high-quality sealant to fill any gaps between panels, ensuring an airtight and water-resistant seal. This step helps to maintain the wall’s durability and insulation.

Smooth the Surface: Use a spatula or putty knife to level the sealant and remove any excess material. This ensures a clean and even finish that blends seamlessly with the wall.

Step 8: Apply Finishing

Plaster or Paint: Depending on your project’s needs, apply plaster, paint, or other finishing materials. This step gives the wall a polished look and adds an extra layer of protection.

Inspect the Work: Carefully check for uneven surfaces, missed gaps, or areas that need touch-ups. Make any necessary adjustments to ensure a high-quality, professional finish.

Pro Techniques for Flawless EPS Wall Panel Installation

Use a Guideline for Alignment

Stretch a chalk line or use a laser level across the wall to maintain straight and even alignment, ensuring that the panels are installed uniformly and without misalignment.

Pre-drill Holes

Pre-drilling holes for anchors helps minimize the risk of cracking or damaging the panels, making the installation process smoother and preserving the integrity of the EPS panels.

Work with a Partner

Although EPS panels are lightweight, they are often large, so having a second person to assist with positioning and holding them in place ensures accuracy and prevents mistakes during installation.

Choose the Right Tools

Use a fine-toothed saw for cutting the panels to reduce the risk of chipping and achieve clean, precise cuts, and use a caulking gun for applying adhesives evenly for a stronger bond.

Insulate Seamlessly

To maximize thermal performance and prevent heat loss, ensure that joints are overlapped or use specialized connectors designed for EPS panels to create a continuous and secure layer.

Allow Adequate Curing Time

Give the adhesive sufficient time to cure as recommended by the manufacturer before applying heavy loads or finishing layers to ensure the bond is strong and durable.

Common Mistakes to Avoid

Skipping Surface Preparation

Failing to clean and level the base can lead to poor adhesive contact, ultimately compromising the strength and durability of the installation.

Overapplying Adhesive

Applying too much adhesive can create excess that seeps out between panels, causing visible seams, and can extend the curing time, leading to delays.

Ignoring Expansion Gaps

EPS panels naturally expand and contract with temperature fluctuations, so it’s essential to leave small, calculated gaps to prevent warping or damage due to movement.

Rushing the Process

Hurrying the installation can result in improper measurements, poor alignment, and an unstable finish, making the project prone to future issues.

Maintenance Tips for EPS Wall Panels

- Regular Cleaning: Wipe panels with a damp cloth or mild detergent to keep them looking new and to prevent the buildup of dirt and grime that can affect their appearance and durability.

- Inspect for Damage: Periodically check for cracks, scratches, or loose sections and repair promptly to avoid further damage and maintain the structural integrity of the panels.

- Protect from Impact: Avoid heavy impacts that could dent, scratch, or damage the panels; this helps maintain their sleek look and prevents long-term damage.

- Avoid Harsh Chemicals: Steer clear of abrasive or harsh cleaning agents that can weaken the material and cause discolouration or deterioration over time.

Conclusion

Installing EPS wall panels can be a straightforward and rewarding process when done correctly. By following the steps outlined in this guide and using the pro techniques provided, you can achieve a professional finish that enhances the durability, insulation, and aesthetics of your building.

Whether you’re a seasoned contractor or a DIY enthusiast, EPS wall panel installation is a fantastic solution for modern construction. Start your project today, and enjoy the benefits of a high-performance wall system that’s built to last!