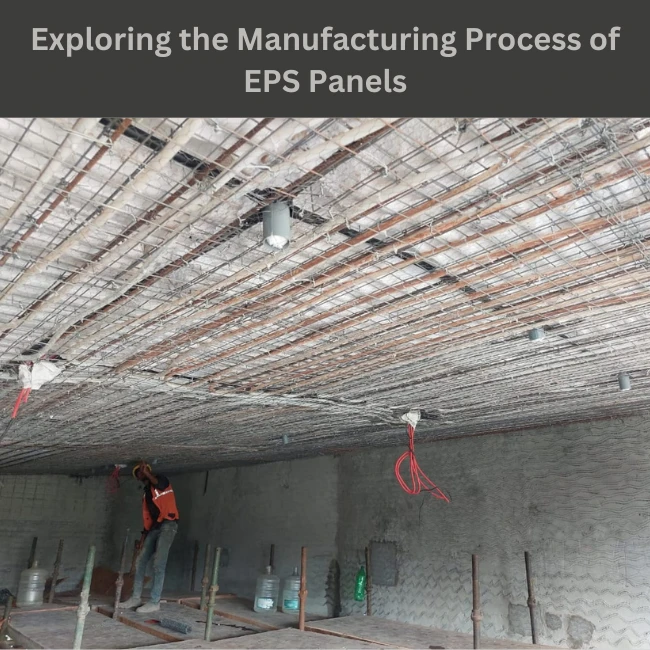

In the realm of construction materials, EPS (Expanded Polystyrene) panels have gained significant attention for their versatility, durability, and insulation properties. These lightweight panels are widely used in various industries, ranging from construction to packaging. Understanding the manufacturing process behind EPS panels sheds light on their composition and benefits. In this comprehensive guide, we delve into the intricacies of how EPS panels are made.

Table of Contents

ToggleWhat is EPS?

Before diving into the manufacturing process, it’s essential to grasp the fundamentals of EPS. EPS is a lightweight cellular plastic material derived from petroleum and natural gas byproducts. It consists of tiny, individual cells that give it excellent insulation properties and structural strength.

Raw Material Preparation:

The manufacturing process of EPS panels begins with the preparation of raw materials. The primary ingredient is expandable polystyrene beads, which are derived from polystyrene resin. These beads undergo a pre-expansion process where they are heated using steam. This causes them to expand to several times their original size, resulting in the characteristic cellular structure of EPS.

Molding Process:

Once the pre-expanded beads are ready, they are transferred into a molding machine. In the molding process, the beads are subjected to heat and pressure inside a mold cavity. The heat causes the beads to fuse together, forming a solid block with the desired shape and dimensions. The pressure ensures uniformity and density throughout the block.

Steam Chest Molding:

Another method of molding EPS panels involves the use of steam chest molding. In this process, the pre-expanded beads are placed in a steam chest, where they are exposed to high-pressure steam. The steam causes the beads to expand further and fuse together, filling the mold cavity. Steam chest molding is particularly suitable for producing large, complex shapes.

Cutting and Shaping:

After molding, the EPS blocks are allowed to cool and solidify before being cut into panels of various sizes and shapes. This cutting process is typically performed using hot wires or saws that can easily slice through the lightweight material. The panels can be customized according to specific requirements, such as thickness and dimensions.

Surface Treatment:

To enhance the properties and appearance of EPS panels, they undergo surface treatments. This may involve applying coatings or laminates to provide additional strength, moisture resistance, or fire retardancy. Surface treatments also enable the panels to be painted or textured to match aesthetic preferences.

Quality Control:

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the EPS panels meet industry standards and specifications. This includes testing the density, thermal conductivity, compressive strength, and other relevant properties of the panels. Any defects or inconsistencies are identified and addressed promptly to maintain product integrity.

Recycling and Sustainability:

One of the notable advantages of EPS panels is their recyclability. EPS can be recycled and reused in various applications, reducing environmental impact and promoting sustainability. Many manufacturers incorporate recycled EPS material into their production processes, further minimizing waste and energy consumption.

Conclusion:

The manufacturing process of EPS panels is a sophisticated and carefully orchestrated series of steps that transform raw materials into versatile building materials. From raw material preparation to quality control, each stage plays a crucial role in producing high-quality EPS panels with excellent insulation properties and structural integrity. Understanding the intricacies of this process highlights the innovation and craftsmanship behind EPS panels and their widespread applications in diverse industries.