In the ever-evolving realm of construction, innovation constantly drives the industry forward, seeking more efficient, sustainable, and cost-effective solutions. One such advancement that has garnered attention is the emergence of EPS concrete panels. These panels, combining expanded polystyrene (EPS) foam with concrete, represent a significant departure from traditional construction materials, offering a myriad of benefits that are reshaping the way buildings are erected and structures are fortified.

Table of Contents

ToggleUnderstanding EPS Concrete Panels

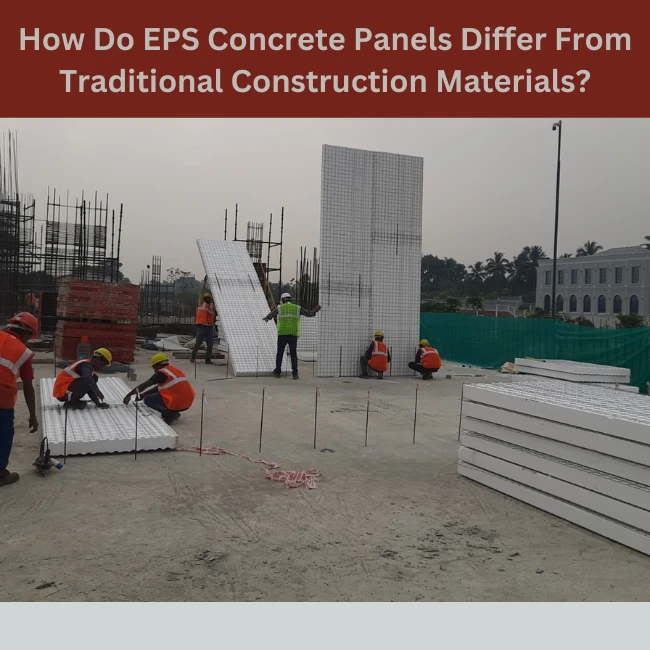

EPS concrete panels are composite building materials made by encapsulating EPS foam within a concrete shell. The EPS foam acts as a lightweight core, providing insulation, while the concrete shell offers strength and durability. This combination results in panels that are lighter, more energy-efficient, and quicker to install compared to traditional building materials like bricks, blocks, or poured concrete.

Advantages Over Traditional Construction Materials

Weight Reduction:

EPS concrete panels are significantly lighter than traditional materials, making them easier to handle and transport. This characteristic not only speeds up construction but also reduces the need for heavy machinery, cutting down on costs and environmental impact.

Insulation Properties:

The EPS foam core in these panels offers excellent thermal insulation properties. This insulation helps regulate indoor temperatures, reducing heating and cooling expenses for buildings. As a result, structures built with EPS concrete panels are more energy-efficient and environmentally friendly.

Speed of Construction:

Since EPS concrete panels are prefabricated off-site, construction time is greatly reduced. This method allows for faster assembly on-site, accelerating project completion timelines. Additionally, the precision of factory manufacturing ensures consistency and quality in each panel, minimizing on-site errors and delays.

Versatility:

EPS concrete panels come in various shapes and sizes, offering flexibility in design and construction. They can be easily customized to fit different architectural styles and building requirements, making them suitable for a wide range of applications, from residential homes to commercial complexes.

Durability:

Despite their lightweight nature, EPS concrete panels are remarkably durable and resistant to weather, fire, and pests. The concrete shell provides structural strength, while the EPS foam core adds impact resistance and resilience, ensuring longevity and low maintenance over the lifespan of the building.

Environmental Sustainability:

By using EPS foam, a recyclable material, in their construction, EPS concrete panels contribute to sustainability efforts in the construction industry. Additionally, the energy efficiency of buildings constructed with these panels helps reduce carbon emissions associated with heating and cooling, further lowering their environmental footprint.

Applications of EPS Concrete Panels

The versatility and benefits of EPS concrete panels make them suitable for various construction projects, including:

Residential buildings: Affordable housing, apartments, and single-family homes.

Commercial structures: Offices, retail spaces, and industrial facilities.

Institutional buildings: Schools, hospitals, and government facilities.

Infrastructure projects: Bridges, sound barriers, and retaining walls.

Conclusion

EPS concrete panels represent a revolutionary approach to construction, offering a blend of efficiency, sustainability, and versatility that traditional building materials struggle to match. With their lightweight design, excellent insulation properties, and durability, these panels are reshaping the way buildings are constructed, promising faster, more cost-effective, and environmentally friendly solutions for the future of construction. As the demand for sustainable and efficient building materials continues to grow, EPS concrete panels are poised to play a significant role in shaping the built environment for generations to come.