In the ever-evolving world of construction, architects, builders, and property owners are constantly seeking innovative materials and techniques that can enhance the durability, energy efficiency, and aesthetics of their buildings. One such revolutionary product that has gained significant attention in recent years is the insulated sandwich panel. This blog post will delve into the benefits of insulated sandwich panels, exploring how they are transforming the construction industry by offering energy-efficient and low-maintenance solutions for various building applications.

Table of Contents

ToggleWhat are Insulated Sandwich Panels?

Insulated sandwich panels, also known as insulated metal panels (IMPs), are pre-engineered, lightweight, and versatile building components. They consist of two outer sheets of metal (usually steel or aluminum) bonded to a rigid thermal insulation core, such as polyurethane or polystyrene foam. The combination of these materials results in a strong, durable, and energy-efficient product that can be used for walls, roofs, and even floors in various construction projects.

Energy Efficiency: The Key Advantage

One of the primary reasons insulated sandwich panels have gained popularity is their exceptional energy efficiency. The insulation core within the panel minimizes heat transfer, keeping the interior of a building warm during winters and cool during summers. This results in reduced energy consumption for heating and cooling systems, leading to lower utility bills and a smaller carbon footprint for building owners. Additionally, insulated sandwich panels can achieve high insulation values, making them suitable for passive house and net-zero energy building projects.

Durability and Low Maintenance

Insulated sandwich panels offer excellent durability due to their robust construction. The metal sheets provide protection against weather elements, such as rain, snow, and wind, while the insulation core ensures the structure remains stable and resistant to temperature fluctuations. This combination of strength and insulation makes insulated sandwich panels ideal for harsh climates and extreme weather conditions.

Moreover, insulated sandwich panels require minimal maintenance, as their non-corrosive and non-absorbent nature prevents the growth of mold and mildew. The smooth surface of the metal sheets is easy to clean, ensuring the panels maintain their aesthetic appeal over time. This low-maintenance characteristic translates into cost savings for building owners, as they can focus on other aspects of building management without worrying about frequent repairs or refurbishments.

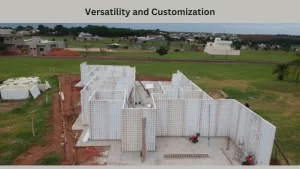

Versatility and Customization

Insulated sandwich panels offer unparalleled versility in terms of design and application. They can be customized to suit various architectural styles and building requirements, making them suitable for a wide range of projects, from commercial and industrial buildings to educational institutions, healthcare facilities, and even residential properties.

The panels can be manufactured in various sizes, colors, and finishes, allowing architects to create visually appealing and unique structures that blend seamlessly with their surroundings. Additionally, insulated sandwich panels can be easily installed, reducing construction time and labor costs. This speedy installation process also minimizes disruptions to ongoing operations, such as in the case of commercial or industrial buildings.

Environmental Benefits

Insulated sandwich panels contribute to a more sustainable built environment in multiple ways. Firstly, their energy-efficient properties help reduce greenhouse gas emissions by lowering the overall energy consumption of buildings. This is in line with worldwide endeavors to address climate change and advance sustainable development.

Secondly, the use of recycled materials in the manufacturing process of insulated sandwich panels reduces waste and conserves natural resources. Many EPS Panels manufacturers in India use recycled steel and aluminum in the outer sheets, while the insulation cores can be made from recycled plastics or other materials. This eco-friendly approach minimizes the environmental impact of these panels throughout their life cycle.

Cost-Effectiveness

While the initial cost of insulated sandwich panels may be higher than traditional building materials, their long-term benefits make them a cost-effective choice. The energy savings, low maintenance requirements, and reduced construction time all contribute to a favorable return on investment for building owners. Furthermore, the panels’ durability ensures that they can withstand the test of time, reducing the need for frequent replacements or repairs.

Closing Remarks

Insulated sandwich panels have emerged as a game-changer in the construction industry, offering energy-efficient, low-maintenance, and versatile building solutions. Their numerous benefits, including durability, customization options, environmental sustainability, and cost-effectiveness, make them an attractive choice for architects, builders, and property owners alike. As the world continues to prioritize energy efficiency and sustainable construction practices, insulated sandwich panels are poised to play a significant role in shaping the future of the built environment.

Also, read

Considering EPS Panels? 7 Factors You Should Take Into Account

FAQs

How do insulated sandwich panels compare to traditional building materials in terms of energy efficiency?

Insulated sandwich panels excel in energy efficiency due to their unique construction, which minimizes heat transfer and reduces reliance on heating and cooling systems. Compared to traditional materials like concrete or brick, insulated sandwich panels offer superior insulation properties, leading to significant energy savings over the lifetime of a building.

Are insulated sandwich panels suitable for all types of climates?

Yes, insulated sandwich panels are highly versatile and can be used in various climates, including both hot and cold regions. Their durable construction and excellent insulation make them ideal for withstanding extreme weather conditions, whether it’s scorching heat, heavy snowfall, or strong winds. Additionally, they are commonly used in passive house designs and net-zero energy buildings, showcasing their adaptability to different environmental contexts.

What maintenance is required for buildings constructed with insulated sandwich panels?

Buildings constructed with insulated sandwich panels require minimal maintenance thanks to their durable and low-maintenance nature. Regular cleaning of the panels’ smooth metal surfaces is typically all that’s needed to maintain their aesthetic appeal. Additionally, since they are non-corrosive and non-absorbent, there’s no risk of mold or mildew growth, reducing the need for costly repairs or refurbishments over time.

Can insulated sandwich panels be recycled at the end of their lifespan?

Yes, many insulated sandwich panels are designed with recyclability in mind. The outer metal sheets can often be recycled, and some manufacturers use recycled steel or aluminum in their production. Additionally, efforts are being made to develop insulation cores that are recyclable or made from environmentally friendly materials. This approach aligns with sustainability goals and reduces the environmental impact of construction materials.

Do insulated sandwich panels require specialized installation techniques?

While insulated sandwich panels do require careful handling during installation for a home to ensure proper sealing and insulation performance, they can be installed using standard construction techniques. Many manufacturers provide detailed installation guidelines, and experienced contractors familiar with working with metal panels can efficiently install them. Their lightweight nature also facilitates faster installation, reducing labor costs and construction time compared to traditional building materials.

Watch Video