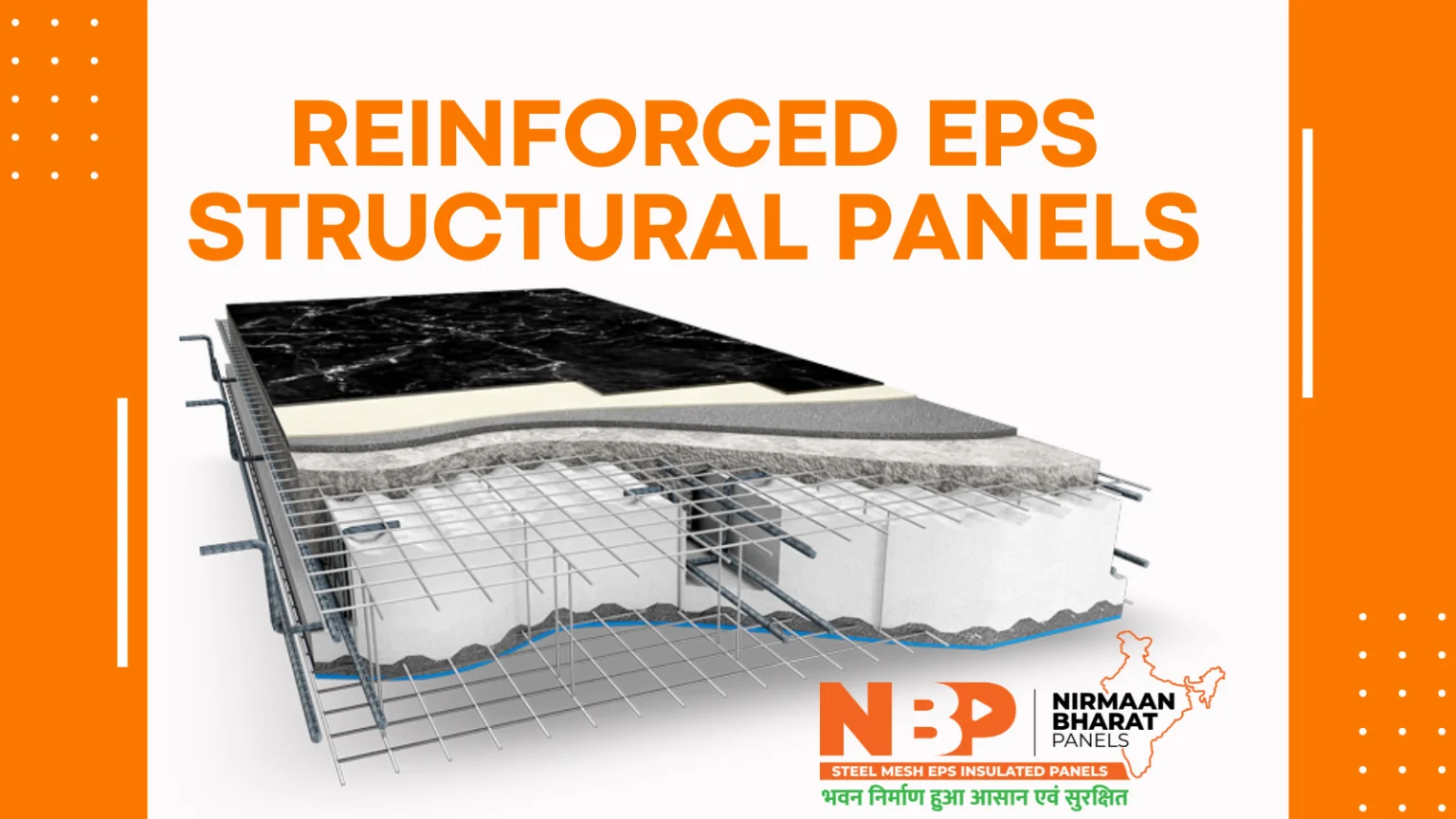

NBP’s Reinforced EPS Structural Panel (RESP) represent a groundbreaking advancement in building technology, offering superior structural integrity, thermal insulation, and sustainability. Certified to meet stringent industry standards, RESP panels are at the forefront of modern construction solutions, ensuring reliability and performance in diverse building applications. This article explores the certifications that validate RESP panels as a cornerstone in innovative building solutions, highlighting their impact on the construction industry.

Table of Contents

ToggleCertifications and Standards

ISO 9001:2000 Certification: NBP maintains ISO 9001:2000 certification, ensuring that RESP panels adhere to rigorous quality management standards. This certification underscores our commitment to consistently delivering high-quality building materials.

Fire Safety Ratings: RESP panels comply with national and international fire safety standards, demonstrating their ability to withstand fire and contribute to building safety.

Environmental Certifications: Environmental certifications, such as ISO 14001, highlight NBP’s commitment to sustainability by minimizing environmental impact throughout the lifecycle of RESP panels.

Advantages of RESP Panels

Structural Integrity: Reinforced EPS Structural Panel (RESP) for enhanced structural strength, making them suitable for a wide range of construction applications, from residential to commercial projects.

Thermal Insulation: With superior thermal insulation properties, RESP panels contribute to energy efficiency, reducing heating and cooling costs for buildings.

Sustainability: RESP panels are eco-friendly, using recyclable materials and promoting sustainable construction practices. They contribute to green building certifications and reduce carbon footprint.

Application in Building Solutions

Versatility: RESP panels are versatile, used in various building types including residential homes, commercial complexes, and industrial facilities.

Innovation: As a cornerstone of innovative building solutions, RESP panels enable faster construction timelines and reduced labor costs, enhancing overall project efficiency.

Customer Confidence: By meeting stringent certifications and standards, RESP panels instill confidence in architects, builders, and developers, ensuring reliable performance and durability.

EPS Panels represents a paradigm shift in construction methodologies, leveraging NBP’s advanced Reinforced EPS Structural Panel (RESP) to redefine industry standards. This innovative building solution integrates superior strength, thermal efficiency, and sustainability, setting new benchmarks in modern construction practices.

Features of EPS Panels

- Reinforced EPS Structural Panel (RESP):

Advanced Composition: RESP panels feature a core of Expanded Polystyrene (EPS) fortified with reinforcement materials such as fibreglass or steel mesh. This composite structure enhances structural integrity while maintaining a lightweight profile.

High Load-Bearing Capacity: Designed to withstand substantial vertical and lateral loads, RESP panels are suitable for a wide range of construction applications, including high-rise buildings and industrial facilities.

Modular Design: Prefabricated RESP panels allow for efficient manufacturing off-site, ensuring precision assembly and expedited construction timelines on-site.

- Thermal Efficiency:

Superior Insulation Properties: EPS Panels excel in thermal insulation, minimizing heat transfer and enhancing energy efficiency within buildings.

Year-Round Comfort: By reducing heating and cooling demands, RESP panels contribute to a comfortable indoor environment throughout the year, optimizing occupant comfort and operational costs.

- Sustainability and Environmental Impact:

Eco-Friendly Materials: NBP prioritizes sustainable practices by using recyclable materials in RESP panels, reducing environmental impact and promoting green building certifications.

Energy Conservation: Enhanced thermal performance of EPS Panels contributes to lower carbon emissions and supports energy-efficient building practices, aligning with global sustainability goals.

- Safety and Durability:

Fire Resistance: RESP panels are engineered to meet stringent fire safety standards, enhancing building safety and compliance with local regulations.

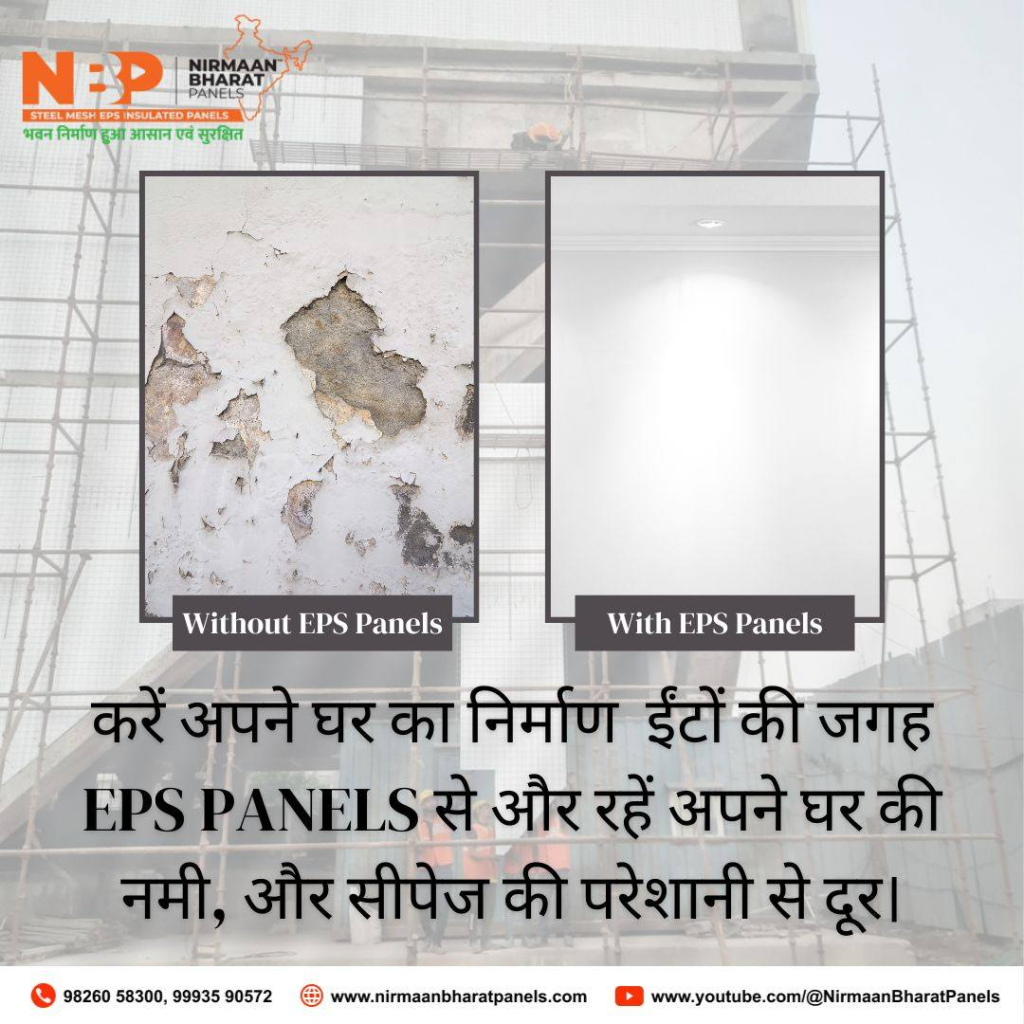

Weather Resistance: Resistant to weathering, moisture, and corrosion, EPS Panels ensure durability and longevity in diverse climatic conditions, minimizing maintenance requirements over time.

- Versatility and Design Flexibility:

Customization Options: EPS Panels in India offer flexibility in panel dimensions, finishes, and architectural aesthetics, accommodating diverse design requirements and project specifications.

Integration Capabilities: RESP panels seamlessly integrate with other building systems, including HVAC, electrical, and plumbing, ensuring compatibility and efficiency in construction.

Benefits of EPS Panels

- Efficiency: Reduced construction timelines and enhanced energy efficiency contribute to cost savings and operational efficiency for developers and building owners.

- Safety and Compliance: The EPS Panel’s adherence to rigorous safety standards and certifications ensures compliance with industry regulations and promotes occupant safety.

- Innovation and Leadership: By pioneering advanced building solutions, EPS Panels positions NBP as a leader in sustainable and efficient construction practices, driving industry innovation.

Soft Body and Water Penetration Tests for EPS Panels

Expanded Polystyrene (EPS) panels are widely used in construction for their insulation properties and versatility. Ensuring their durability and performance requires comprehensive testing methods, including soft body and water penetration tests. This article explores the significance of these tests in evaluating EPS panels and ensuring their suitability for various construction applications.

Soft Body Impact Test

The soft body impact test is crucial for assessing the impact resistance and structural integrity of EPS panels, particularly in scenarios where accidental impacts may occur during handling, installation, or use. Here’s how the test is conducted and its implications:

Conducting the Test:

- Procedure: A weighted, soft-bodied impactor is dropped onto the EPS panel from a specified height.

- Measurement: The test measures the extent of deformation and damage inflicted on the panel.

- Criteria: EPS panels should demonstrate minimal deformation and maintain their structural integrity to pass the test.

Implications:

- Durability: Panels that withstand soft body impacts without significant damage are deemed durable and suitable for construction applications.

- Safety: Ensures panels can withstand minor accidental impacts without compromising structural stability.

Water Penetration Test

Water penetration testing evaluates the ability of EPS panels to resist water ingress, which is critical for maintaining their insulation properties and preventing moisture-related issues in buildings:

Conducting the Test:

- Procedure: EPS panels are exposed to a controlled amount of water through spraying or immersion.

- Observation: The test assesses whether water penetrates through the panel or if it remains effectively waterproof.

- Criteria: Panels should resist water penetration to maintain their insulation effectiveness and prevent structural damage.

Implications:

- Insulation Integrity: Effective water resistance ensures that EPS panels maintain their insulation properties over time.

- Preventing Damage: Minimizes the risk of mold growth, structural degradation, and other moisture-related issues in buildings.

Importance in Construction Applications

1. Quality Assurance

Soft body and water penetration tests are integral to quality assurance processes for EPS panels. They validate manufacturers’ claims regarding durability, impact resistance, and water resistance.

2. Building Code Compliance

Compliance with testing standards ensures that EPS panels meet regulatory requirements for construction materials, promoting safety and reliability in building projects.

3. Performance in Varied Conditions

Testing under controlled conditions simulates real-world scenarios, ensuring EPS panels perform reliably in diverse environmental conditions, including extreme weather events.

Conclusion

NBP’s Reinforced EPS Structural Panel (RESP) represent a transformative approach to modern construction, integrating superior strength, thermal insulation, and sustainability into one innovative solution. Backed by certifications that validate their quality and reliability, RESP panels are reshaping the construction landscape by offering efficient and sustainable building solutions for today’s and tomorrow’s challenges. Soft body impact and water penetration tests are essential for assessing the durability, impact resistance, and water resistance of EPS panels used in construction. By undergoing these rigorous tests, manufacturers can validate the quality and reliability of their products, ensuring they meet industry standards and regulatory requirements. As the construction industry continues to prioritize sustainability and efficiency, these tests play a crucial role in ensuring EPS panels contribute to durable, energy-efficient, and resilient building solutions.

At NBP, transparency and reliability are paramount pillars of our commitment to delivering top-tier construction solutions. Our commitment to quality assurance is demonstrated by our adherence to strict certification requirements and thorough testing results. By maintaining these standards, we ensure that our EPS panels meet and exceed industry benchmarks for durability, safety, and performance. This commitment not only enhances customer trust but also reinforces our position as a leader in providing sustainable and innovative building materials for diverse construction needs.