In the quest for improving earthquake resilience in construction, Thermocol, or Game Changer eps panel, has emerged as a groundbreaking material. EPS’s unique properties offer significant advantages in enhancing the earthquake resistance of structures, particularly in multi-storey buildings. This report explores how EPS is revolutionizing earthquake-resistant construction, its benefits, and the technological advancements driving its use.

Table of Contents

ToggleUnderstanding EPS and Its Properties

1. What is EPS? Expanded Polystyrene (EPS) is a lightweight, rigid foam material made from expanded polystyrene beads. These beads are expanded and fused together through a heat process, creating a foam with numerous small, closed cells.

Researchers at IIT Roorkee have demonstrated that Expanded Polystyrene (EPS), or thermocol, can significantly enhance the earthquake resistance of multi-storey buildings. Here’s how:

Key Findings:

- Reduced Mass and Improved Earthquake Resistance:

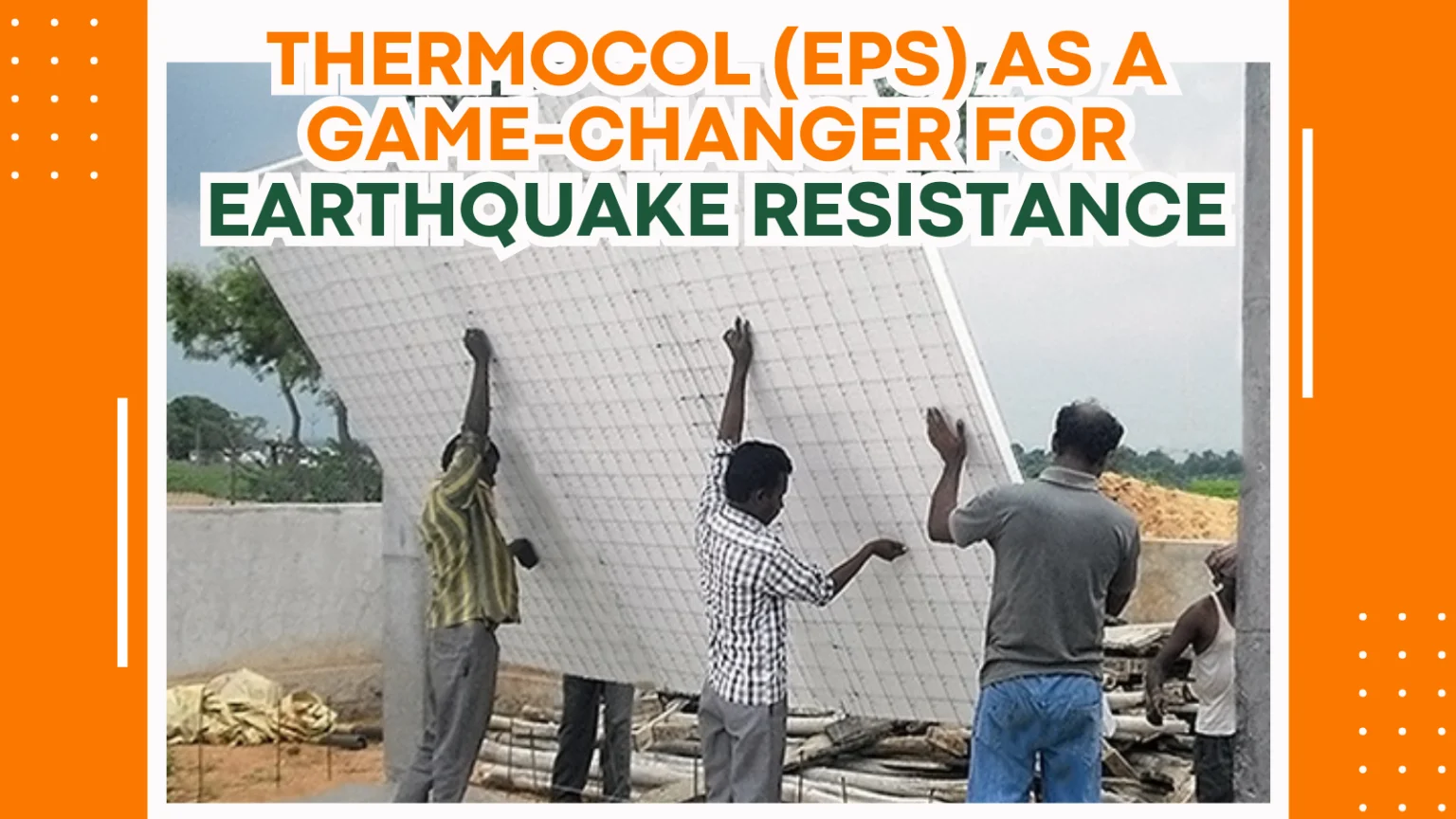

- Game Changer eps panel is encased between two layers of concrete, which are reinforced with welded wire mesh. This configuration helps in reducing the overall mass of the building, which in turn decreases the seismic forces acting on the structure during an earthquake.

- Testing and Performance:

- Full-scale tests at the National Seismic Test Facility (NSTF) of IIT Roorkee showed that buildings with Game Changer eps panel cores can withstand earthquake forces effectively. The reduced mass of the EPS core lessens the inertia effects during seismic events.

- Construction Efficiency:

- The EPS core and wire mesh are produced in a factory and assembled on-site. Concrete is then sprayed onto the pre-assembled core. This method eliminates the need for traditional shuttering, speeding up construction and reducing labor costs.

- Thermal Comfort:

- Game Changer eps panel provides excellent thermal insulation, keeping interiors cool in hot climates and warm in cold conditions ranging from 0.032 to 0.038 W/(m·K). This feature is particularly beneficial in regions with significant temperature variations, such as India.

- Sustainability and Energy Efficiency:

- Using Game Changer eps panel reduces the amount of concrete needed, thereby lowering the overall carbon footprint of construction. It also conserves natural resources by decreasing the demand for cement and sand.

- Moisture Resistance: Closed-cell structure provides good resistance to moisture and water ingress.

- Impact Resistance: Capable of absorbing impact and reducing structural damage during seismic activities.

Role of EPS in Earthquake-Resistant Construction

1. Reducing Building Mass The lightweight nature of EPS significantly reduces the overall mass of a building. In seismic events, the force exerted on a building is proportional to its mass. By reducing the mass of the structure, EPS lowers seismic forces and thereby diminishes the potential for structural damage.

2. Enhancing Flexibility and Load Distribution EPS, when used as a core material in sandwich panels, contributes to improved flexibility and load distribution. This flexibility enables the building to better absorb and dissipate seismic energy, decreasing the likelihood of catastrophic failure.

3. Structural Reinforcement EPS is typically sandwiched between layers of reinforced concrete. This construction method enhances the structural integrity of buildings. The concrete layers, reinforced with welded wire mesh, provide strength and stability, while the EPS core contributes to reduced weight and improved insulation.

4. Proven Effectiveness Recent studies and tests have demonstrated the effectiveness of Game Changer eps panel in earthquake-resistant applications. For instance, research at IIT Roorkee has shown that buildings with EPS cores can withstand significant seismic forces, making them suitable for up to four-storey structures.

Technological Advancements

1. Integration with Modern Construction Techniques EPS is increasingly being integrated into advanced construction techniques, such as prefabricated panels and modular construction. These methods streamline the construction process, allowing for quicker assembly and enhanced seismic performance.

2. Improved EPS Formulations Ongoing research is focusing on enhancing the performance of EPS through improved formulations and treatments. These advancements aim to further increase its seismic resistance, fire performance, and durability.

3. Smart Monitoring Systems Innovations in sensor technology are enabling the integration of smart monitoring systems within EPS-based structures. These systems can provide real-time data on structural health and seismic activity, allowing for proactive maintenance and safety measures.

Case Studies and Real-World Applications

1. Residential Buildings EPS has been used in residential construction to achieve high earthquake resistance while maintaining energy efficiency. Homes constructed with EPS core panels have demonstrated improved stability during seismic events, with reduced structural damage.

2. Commercial Buildings In commercial buildings, EPS core panels have enhanced performance in terms of both seismic resistance and thermal insulation. The reduced mass and improved flexibility of these structures contribute to their overall resilience and efficiency.

3. Infrastructure Projects EPS is also used in infrastructure projects, such as bridges and retaining walls, where its lightweight and impact-absorbing properties help mitigate seismic forces and improve durability.

Benefits of Using EPS in Earthquake-Resistant Construction

1. Cost Savings By reducing the amount of concrete required and speeding up construction time, EPS can lead to significant cost savings in both materials and labor.

2. Enhanced Safety The use of EPS improves the safety of buildings by reducing the risk of collapse during earthquakes and enhancing overall structural integrity.

3. Environmental Impact EPS’s role in reducing concrete usage also contributes to a lower carbon footprint. Additionally, EPS can be produced using recycled materials, further minimizing environmental impact.

4. Thermal Comfort In addition to its seismic benefits, EPS provides excellent thermal insulation, contributing to energy efficiency and comfort in various climatic conditions.

Read More: How to Keep Your Home Cool in Summer Insulation Tips and Tricks

Challenges of Thermocol (EPS)

Thermocol, commonly known as Expanded Polystyrene (EPS), is a popular material used for thermal insulation in various applications, including construction, packaging, and more. While EPS offers numerous benefits, it also comes with certain challenges and considerations. Here’s a detailed look at these aspects:

1. Environmental Impact

- Non-Biodegradable: EPS does not break down naturally and can remain in the environment for hundreds of years, contributing to landfill waste.

- Recycling Issues: While EPS can be recycled, the infrastructure for recycling EPS is often limited, making it less commonly recycled compared to other materials.

2. Fire Performance

- Flammability: EPS is highly flammable and can emit toxic fumes when burned. Fire-resistant additives and treatments can improve its fire performance, but it still poses a risk in high-temperature conditions.

- Building Codes: Due to its flammability, EPS often requires special treatment or covering to meet building codes and fire safety standards.

3. Durability and Aging

- Degradation: EPS can degrade over time due to UV exposure and environmental conditions, leading to reduced performance and structural integrity.

- Impact Resistance: Although EPS is lightweight and shock-absorbent, it can be prone to physical damage from impacts or compression.

4. Moisture Sensitivity

- Water Absorption: While EPS has low water absorption, prolonged exposure to moisture can cause it to lose some of its insulating properties and structural strength.

- Damp Environments: In construction, proper sealing and protection are needed to prevent moisture infiltration and ensure long-term performance.

5. Cost Considerations

- Initial Cost: EPS is generally cost-effective, but the price can vary based on density, thickness, and additives. The overall cost also includes handling, installation, and potential future replacement.

Considerations for Using Thermocol (EPS)

1. Insulation Performance

- Thermal Conductivity: EPS provides good thermal insulation with a typical thermal conductivity of around 0.035-0.040 W/mK. It effectively reduces heat transfer and enhances energy efficiency.

- R-Value: The R-value of EPS panels increases with thickness. Ensure that the chosen thickness meets the specific insulation requirements for the application.

2. Building Codes and Standards

- Compliance: Ensure that EPS used in construction complies with local building codes and regulations, especially those related to fire safety and thermal performance.

- Certification: Look for EPS products that have been tested and certified by relevant authorities to ensure they meet quality and safety standards.

3. Installation Practices

- Handling: EPS is lightweight and easy to handle but can be easily damaged by improper handling. Care should be taken to avoid compression and physical damage during transport and installation.

- Sealing: Proper sealing and integration with other building materials are crucial to prevent gaps and ensure effective insulation and moisture protection.

4. Environmental Considerations

- Sustainability: Explore options for EPS with recycled content or look for suppliers who offer recycling programs to minimize environmental impact.

- Alternatives: Consider alternative insulation materials with better environmental profiles, such as cellulose, mineral wool, or polyisocyanurate (PIR), depending on the specific needs and constraints of your project.

5. Performance Monitoring

- Long-Term Performance: Regular inspection and maintenance of EPS installations can help identify and address issues such as degradation or moisture infiltration.

- Adaptation: Be prepared to adapt to changing regulations and advancements in insulation technology, which might offer improved performance or environmental benefits.

EPS is a versatile material offering effective thermal insulation and cost benefits. However, its use comes with challenges related to environmental impact, fire safety, durability, and moisture sensitivity. By considering these factors and implementing appropriate measures, you can optimize the performance of EPS while addressing its potential drawbacks.

Conclusion

Thermocol (EPS) has proven to be a transformative material in the realm of earthquake-resistant construction. Its lightweight, flexibility, and insulating properties make it a valuable asset in enhancing building resilience and safety. As technological advancements continue to evolve, EPS is likely to play an even more significant role in shaping the future of earthquake-resistant design and construction.